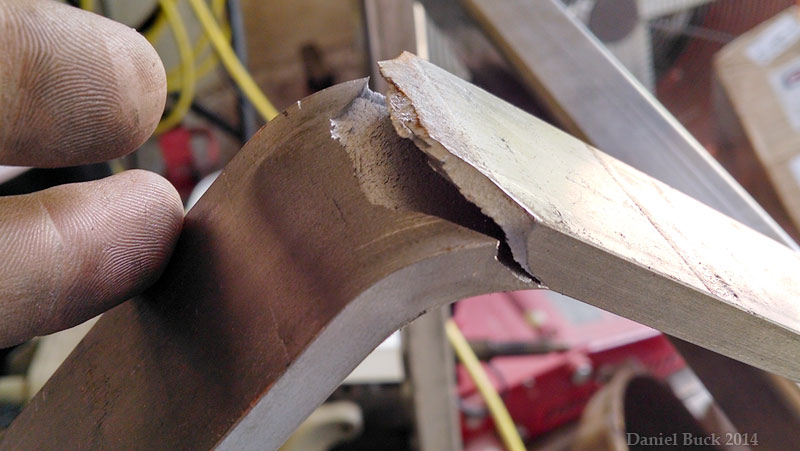

It looks a little different than the normal mild steel that I get, but I figured it just had a different type of mill scale or something. But now that I look at it closer, it doesn't really have any mill scale on it, just a dull shine.

I think I have a few other flat bars out of this same stuff, including some nice 4" wide 5/8" thick stuff that appears to have the same finish on it. I just hadn't gotten around to actually using that stuff yet. I picked it up because it was thicker than the flat bar that I usually see in the scrap section. The one in this photo is 2" wide 1/4" thick I think.

Any idea what it is? Apparently it's not bendable (without heat anyway). Is it weldable? What can I use this for?

Can I at least use it for gussets and feet/plates what not that don't need to be bent? I probably should have looked at it closer before I picked it out.