Have a look at that video from weld com

https://youtu.be/bjB0I3HXIVc?t=12m40s

He tries to run 6010 DC but the welder does not accept it (not enough OCV voltage) the arc stops again and again , it may restart due to the hot start feature sending the max voltage but the arc cannot be maintained well.

There are some moments where the front panel is in the picture, showing the real amps used

So it is regulated at 80A, we see at each start a raise to 147A which seem to be the standard (regulated?) hot start level for that machine (lowering progressively immediately, hot start is said to have a few milliseconds duration so it goes fast)

But what interested me is to see that from 80A the welding is done in the end at about 100

I wonder if this is the arc force function that add those 20A when he uses a short arc. From 80A the amps are not stable and move a lot.

But later in the video he uses 105AMP, then the machine rise at 120 A and is a little more stable at that power

see https://youtu.be/bjB0I3HXIVc?t=24m29s

then he uses 130A , the machine jumps to 150 and barely moves 1-3A p (I think I understand, this welder allows to regulate an "overheat" feature, - should be the dig function ? - so the amps where regulated at 130, and overheat at 150.

Then the drag did put the arc at its max AMPS 150 at all times

https://youtu.be/bjB0I3HXIVc?t=27m14s

I wonder if that is not one of the reason why many like to use the high range of amps, stability.

I feel those amps changes when welding, that tend to make a more erratic arc due to my lack of precision, but when I put arc force/dig to 10% or zero I FEEL a more stable arc, an arc that do not change as much in heat with my little length variations.

That sound stupid, as arc force is sold as an arc stabilizer , I wonder if the function is not on systematically when one use a short tense arc, dragging or almost.

What do you think of those observations ?

PS I find that interesting article on the Miller's site https://www.millerwelds.com/resources/a ... g-purposes

Stick Welding Tips, Certification tests, machines, projects

Yes, certainly, but do you think that once regulated for instance at 105 AMps, you weld with a short arc and the amps raise 15 amps .Poland308 wrote:Arc length plays a big part in variations of amps on the display as you weld.

I think it may not work that way, all the amps above the initial regulation are due to the dig function.

If one use a long arc from a 105 Amps regulation, then amps will lower (heat lowers) and tension raise.May be one of the causes for the thicker beads created with a long arc (higher tension = higher projection of metal (tension being seen as the pressure in a water tubing, I find this comparison good)

Regards

Pianos , restorer and tuner

Dedicated to learn welding since april

slowly learning not complaining of doing beads and beads

not complaining of doing beads and beads

pro inverter PROGYS 200 FV PFC CEL+tig lift

OA Oxyflam 1000 cutting and welding gas torch

Dedicated to learn welding since april

slowly learning

pro inverter PROGYS 200 FV PFC CEL+tig lift

OA Oxyflam 1000 cutting and welding gas torch

That I don't know but the graphs show only a modified curve where the amps are boosted more or less when tension is under a certain levelPoland308 wrote:Unless you have a poor or intermittent arc then I believe it only boosts the amps for a second or two. No longer.

During those 2 seconds the welder have ample time to shorten the arc if the rod is diminishing fast)

But on the display in the video the amps are raised systematically and all along. (and the arc is mainteined short all the time)

Regards

Pianos , restorer and tuner

Dedicated to learn welding since april

slowly learning not complaining of doing beads and beads

not complaining of doing beads and beads

pro inverter PROGYS 200 FV PFC CEL+tig lift

OA Oxyflam 1000 cutting and welding gas torch

Dedicated to learn welding since april

slowly learning

pro inverter PROGYS 200 FV PFC CEL+tig lift

OA Oxyflam 1000 cutting and welding gas torch

Poland308 wrote:Then something more was going on. It wasn't from the dig setting.

Hello, I suppose you feel when the dig is activated due to a short arc

ON the videos He turns the "peak" or "main heat" button to 150 (last regulation, the left button regulates only the starting Amps . So you may be right this is not a dig function (but it sound as if it is in a similar amps range, that machine have no dig function, only peaks for pulse mode, I dont know how that translate when in MMA)

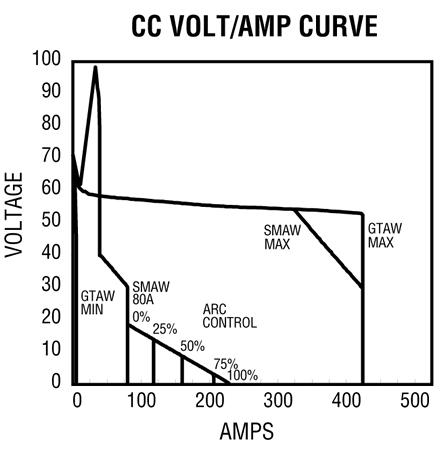

I find that graph that shows simply that if the welder have a dig function, you can weld in the "dig" domain at all times

If the machine is powerful enough it may not cause trouble to work with low current and high amperage for a long time.

ALso if the "effect" would be only for a few seconds, that would not be very nice you would be welding in a good configuration and then suddenly the heat change ? Welders would not accept that .

I think this is the anti stick function that works that way, sending suddenly a strong setting so to burn the rod and avoid sticking ,not the dig, as the dig may be doing the same thing but just by modifying the welding curve)

On the graph I see that it is possible to work within the modified part of the curve at all times

That we see that on the amps display I am not sure but it sound credible

Pianos , restorer and tuner

Dedicated to learn welding since april

slowly learning not complaining of doing beads and beads

not complaining of doing beads and beads

pro inverter PROGYS 200 FV PFC CEL+tig lift

OA Oxyflam 1000 cutting and welding gas torch

Dedicated to learn welding since april

slowly learning

pro inverter PROGYS 200 FV PFC CEL+tig lift

OA Oxyflam 1000 cutting and welding gas torch

Josh you are right

in the end we may not see it really clearly when the arc force is on, As it is just a modification of the current curve may be a sudden rise of amps can be seen but it may only take in account a few amps (not 10-15 or more )

Now it seem that arc force is defined as a temporary raise of amps but only when the arc is short enough to induce sticking. That would mean it burns very fast a little metal to enlarge the arc

It would be even shorter than when dragging at the edge of the puddle ?

May be I can have an idea of the amount, if welder maker tells me how many volts are used or injected to reinforce the arc when the dig function is on

At that point I have no idea . Too bad I was happy to see a demonstration of my "theory" (we can weld in the arc force part of the curve)

Regards

in the end we may not see it really clearly when the arc force is on, As it is just a modification of the current curve may be a sudden rise of amps can be seen but it may only take in account a few amps (not 10-15 or more )

Now it seem that arc force is defined as a temporary raise of amps but only when the arc is short enough to induce sticking. That would mean it burns very fast a little metal to enlarge the arc

It would be even shorter than when dragging at the edge of the puddle ?

May be I can have an idea of the amount, if welder maker tells me how many volts are used or injected to reinforce the arc when the dig function is on

At that point I have no idea . Too bad I was happy to see a demonstration of my "theory" (we can weld in the arc force part of the curve)

Regards

Pianos , restorer and tuner

Dedicated to learn welding since april

slowly learning not complaining of doing beads and beads

not complaining of doing beads and beads

pro inverter PROGYS 200 FV PFC CEL+tig lift

OA Oxyflam 1000 cutting and welding gas torch

Dedicated to learn welding since april

slowly learning

pro inverter PROGYS 200 FV PFC CEL+tig lift

OA Oxyflam 1000 cutting and welding gas torch

Poland308 wrote:I said "dig". But meant hot start. Sry.Poland308 wrote:Then something more was going on. It wasn't from the dig setting.

AH ! OK

I had a look at the manual of that welder, and there is a knob for starting amps level and another for peak , this is used to regulate pulse in tig mode, but influence also the stick mode

What we see is the raise from the start amp to the main level regulation , then back at the end of the job

That said the welder have no dig function and no hot start ,but that possibly have a similar effect than the dig, AS I understand it a stronger voltage create a more invasive arc so any regulation that will modify the voltage will influence the curve is not it ?

Regards

Pianos , restorer and tuner

Dedicated to learn welding since april

slowly learning not complaining of doing beads and beads

not complaining of doing beads and beads

pro inverter PROGYS 200 FV PFC CEL+tig lift

OA Oxyflam 1000 cutting and welding gas torch

Dedicated to learn welding since april

slowly learning

pro inverter PROGYS 200 FV PFC CEL+tig lift

OA Oxyflam 1000 cutting and welding gas torch

Yes. But I think on some machines it affects the arc in more ways than just the voltage. Probably have to get some others to weigh in who are more knowledgeable.

I have more questions than answers

Josh

Josh

Poland308 wrote:Yes. But I think on some machines it affects the arc in more ways than just the voltage. Probably have to get some others to weigh in who are more knowledgeable.

Well it is difficult to find precise descriptions .

Some say that this is only a short timed action when the arc is so short that the stick could stick, then it burns quick a piece of rod and the arc enlarge

Or the arc behavior is changed from its begin moment on the welding curve (I prefer that one)

Or both process are coded in the electronics, some voltage is injected at some point allowing the arc to dig better, plus a security for the really too short arc

Anyway I'd like to know if dragging the rod at the edge of the puddle is short enough to active arc force

I think I can feel it when doing 3F , with the stick right or left that is digging strong

ANd that only with not too powerful regulation, at 120A for 1/8 for instance the arc is so lively and strong there is no feel to reduce it.

Regards

Pianos , restorer and tuner

Dedicated to learn welding since april

slowly learning not complaining of doing beads and beads

not complaining of doing beads and beads

pro inverter PROGYS 200 FV PFC CEL+tig lift

OA Oxyflam 1000 cutting and welding gas torch

Dedicated to learn welding since april

slowly learning

pro inverter PROGYS 200 FV PFC CEL+tig lift

OA Oxyflam 1000 cutting and welding gas torch

Hello

I amnot confusing those but

I am sorry "antistick" function is just cutting the current if the rod have stick, so it does not burn and it is easier to take it out

I was confusing with the arc force, , the result of arc force is that sticking is less easy as when there is a light shortage the electronics send some tension and burn the rod a mm or so

Possibly the amount of shortage is evaluated with its resistance in ohms (or the resulting tension) , during welding, I suspect the tension injection occur with a really small arc as 1 or 2/32

It is logical that the result differs depending of the electrode, the ones that "spray" metal are making less current shortage than the ones that make drops (7018 I think ?)

Regards

I amnot confusing those but

I am sorry "antistick" function is just cutting the current if the rod have stick, so it does not burn and it is easier to take it out

I was confusing with the arc force, , the result of arc force is that sticking is less easy as when there is a light shortage the electronics send some tension and burn the rod a mm or so

Possibly the amount of shortage is evaluated with its resistance in ohms (or the resulting tension) , during welding, I suspect the tension injection occur with a really small arc as 1 or 2/32

It is logical that the result differs depending of the electrode, the ones that "spray" metal are making less current shortage than the ones that make drops (7018 I think ?)

Regards

Pianos , restorer and tuner

Dedicated to learn welding since april

slowly learning not complaining of doing beads and beads

not complaining of doing beads and beads

pro inverter PROGYS 200 FV PFC CEL+tig lift

OA Oxyflam 1000 cutting and welding gas torch

Dedicated to learn welding since april

slowly learning

pro inverter PROGYS 200 FV PFC CEL+tig lift

OA Oxyflam 1000 cutting and welding gas torch

I was said that the voltage is used to regulate the amps on dc machines, the amps possibly are raised by using a stronger voltage (anyway one need more volts to allow more amps, if I understand correctly)Poland308 wrote:Yes. But I think on some machines it affects the arc in more ways than just the voltage. Probably have to get some others to weigh in who are more knowledgeable.

Pianos , restorer and tuner

Dedicated to learn welding since april

slowly learning not complaining of doing beads and beads

not complaining of doing beads and beads

pro inverter PROGYS 200 FV PFC CEL+tig lift

OA Oxyflam 1000 cutting and welding gas torch

Dedicated to learn welding since april

slowly learning

pro inverter PROGYS 200 FV PFC CEL+tig lift

OA Oxyflam 1000 cutting and welding gas torch

I think this is the way the relationship works when you have a given voltage they are used as a reservoir for ampsPoland308 wrote:Usually the volts amps relationship would be inverse. as voltage goes up amps go down.

but if then you add volts the amps will rise I think.

Regards

Pianos , restorer and tuner

Dedicated to learn welding since april

slowly learning not complaining of doing beads and beads

not complaining of doing beads and beads

pro inverter PROGYS 200 FV PFC CEL+tig lift

OA Oxyflam 1000 cutting and welding gas torch

Dedicated to learn welding since april

slowly learning

pro inverter PROGYS 200 FV PFC CEL+tig lift

OA Oxyflam 1000 cutting and welding gas torch

- MinnesotaDave

-

Weldmonger

-

Posts:

-

Joined:Sun Oct 27, 2013 10:57 pm

-

Location:Big Lake/Monticello MN, U.S.A.

Josh is right. As voltage increases (arc longer) the amps decrease.olek wrote:I think this is the way the relationship works when you have a given voltage they are used as a reservoir for ampsPoland308 wrote:Usually the volts amps relationship would be inverse. as voltage goes up amps go down.

but if then you add volts the amps will rise I think.

Regards

This is only true on non-inverters though.

Inverters generally hold the amps as the arc length changes within a certain range.

Dig allows the amps to increase as the voltage reduces (shorter arc) past a set point.

Dave J.

Beware of false knowledge; it is more dangerous than ignorance. ~George Bernard Shaw~

Syncro 350

Invertec v250-s

Thermal Arc 161 and 300

MM210

Dialarc

Tried being normal once, didn't take....I think it was a Tuesday.

Beware of false knowledge; it is more dangerous than ignorance. ~George Bernard Shaw~

Syncro 350

Invertec v250-s

Thermal Arc 161 and 300

MM210

Dialarc

Tried being normal once, didn't take....I think it was a Tuesday.

MinnesotaDave wrote:Josh is right. As voltage increases (arc longer) the amps decrease.olek wrote:I think this is the way the relationship works when you have a given voltage they are used as a reservoir for ampsPoland308 wrote:Usually the volts amps relationship would be inverse. as voltage goes up amps go down.

but if then you add volts the amps will rise I think.

Regards

This is only true on non-inverters though.

Inverters generally hold the amps as the arc length changes within a certain range.

Dig allows the amps to increase as the voltage reduces (shorter arc) past a set point.

You are both right but I talk of something else

Let's say you regulate at 100 Amps, then the welder will use (i.e.) 20V

That voltage allows to obtain 100 Amps with the shorter arc, and may be the volts used are rising when the arc increase, just to maintain the arc . may be at 100 AMPS and with the little arc, the voltage is lower.

In any case I see the voltage as a reserve of power that allows to create x AMPS . If you want to obtain more amps during welding, the only solution I see is to raise the voltage.

To keep the amps while changing the arc length, I suppose we need to be in arc force mode .

In the sketch below , arc force begin at 80A , and 20v that is not what I thought, but I don't know how much amps change depending of the arc length. but what is said here correspond to what I perceived :

(with arc force at 5-6 )"For deeper penetration, simply decrease arc length by pushing the rod into the joint. At this point—and only at this point—the arc force control will kick in and provide the necessary boost of current. To reiterate: operators will only experience arc force when they reduce arc length to a point where voltage levels drop below 20 volts on most machines."

The external characteristics of the welder gives the curve AMPS VOLT where depending of the slant we see how much the volts and amps varies,

For instance if it is a TIG inverter, the curve have a straight slant with a small inclination , a Constant Current curve.

"—The CC volt/amp curve of an inverter “changes personalities” when switched from Stick to TIG modes. Also, notice how the percentages for arc force control increase amperage as voltage drops."

From Miller 's page : https://www.millerwelds.com/resources/a ... g-purposes

Under normal arc length conditions, a Stick electrode operates at about 20 volts. However, some welding situations demand shorter arc lengths, such as when the operator has to push the rod into a tight corner or into a deep bevel of an open root joint. In these situations, Stick electrodes are notoriously prone to living up to their namesake and “sticking the rod” (e.g., the voltage drops so low that the arc extinguishes itself). Arc force control overcomes this problem by increasing current when the voltage levels drop below about 20 volts (see Fig. 3). The boost of current increases total power, keeps the weld puddle molten, prevents the rod from sticking and eliminates a lot of operator frustration.

Pianos , restorer and tuner

Dedicated to learn welding since april

slowly learning not complaining of doing beads and beads

not complaining of doing beads and beads

pro inverter PROGYS 200 FV PFC CEL+tig lift

OA Oxyflam 1000 cutting and welding gas torch

Dedicated to learn welding since april

slowly learning

pro inverter PROGYS 200 FV PFC CEL+tig lift

OA Oxyflam 1000 cutting and welding gas torch

May be there are 2 modules, one that maintain amps when the arc enlarges, and one that add amps and tension when the stick is touching the metal.

Pianos , restorer and tuner

Dedicated to learn welding since april

slowly learning not complaining of doing beads and beads

not complaining of doing beads and beads

pro inverter PROGYS 200 FV PFC CEL+tig lift

OA Oxyflam 1000 cutting and welding gas torch

Dedicated to learn welding since april

slowly learning

pro inverter PROGYS 200 FV PFC CEL+tig lift

OA Oxyflam 1000 cutting and welding gas torch

There is. The mode of operation for stick welding is called "Constant Current". There is also "Constant Voltage" and various hybrid technologies in between.olek wrote:May be there are 2 modules, one that maintain amps when the arc enlarges, and one that add amps and tension when the stick is touching the metal.

Within that mode, there are control features designed to address specific situations by automatically controlling the characteristics of the welding arc, like "dig" or "arc force". This is a sub-system that operates within the system of constant current. How that control is is managed varies from manufacturer to manufacturer, and has changed thanks to technological developments in circuit controls, making it possible to increase current when needed automatically and reduce it when not necessary.

Thank you, I have trouble understanding the sketches in the sketch below (tig inverter) there are 2 CC curve, does it mean there may be a different curve for each amps setting (the stick curve her being for 80A ) ?PeteM wrote:There is. The mode of operation for stick welding is called "Constant Current". There is also "Constant Voltage" and various hybrid technologies in between.olek wrote:May be there are 2 modules, one that maintain amps when the arc enlarges, and one that add amps and tension when the stick is touching the metal.

Within that mode, there are control features designed to address specific situations by automatically controlling the characteristics of the welding arc, like "dig" or "arc force". This is a sub-system that operates within the system of constant current. How that control is is managed varies from manufacturer to manufacturer, and has changed thanks to technological developments in circuit controls, making it possible to increase current when needed automatically and reduce it when not necessary.

Regards and thanks again for chiming in .

Pianos , restorer and tuner

Dedicated to learn welding since april

slowly learning not complaining of doing beads and beads

not complaining of doing beads and beads

pro inverter PROGYS 200 FV PFC CEL+tig lift

OA Oxyflam 1000 cutting and welding gas torch

Dedicated to learn welding since april

slowly learning

pro inverter PROGYS 200 FV PFC CEL+tig lift

OA Oxyflam 1000 cutting and welding gas torch

olek wrote:Thank you, I have trouble understanding the sketches in the sketch below (tig inverter) there are 2 CC curve, does it mean there may be a different curve for each amps setting (the stick curve her being for 80A ) ?PeteM wrote:There is. The mode of operation for stick welding is called "Constant Current". There is also "Constant Voltage" and various hybrid technologies in between.olek wrote:May be there are 2 modules, one that maintain amps when the arc enlarges, and one that add amps and tension when the stick is touching the metal.

Within that mode, there are control features designed to address specific situations by automatically controlling the characteristics of the welding arc, like "dig" or "arc force". This is a sub-system that operates within the system of constant current. How that control is is managed varies from manufacturer to manufacturer, and has changed thanks to technological developments in circuit controls, making it possible to increase current when needed automatically and reduce it when not necessary.

Regards and thanks again for chiming in .

Well so the arc force regulation , when there is one, , is possibly the "fine setting" ? WIth zero arc force I noticed a very buttery arc, not so unpleasant but I did put arc force back trying 10 20 30 until I find a strenght that suits my need

Mixing that regulation and amps is more difficult, at that point I do not understand yet very well what makes what.

But its coming

Pianos , restorer and tuner

Dedicated to learn welding since april

slowly learning not complaining of doing beads and beads

not complaining of doing beads and beads

pro inverter PROGYS 200 FV PFC CEL+tig lift

OA Oxyflam 1000 cutting and welding gas torch

Dedicated to learn welding since april

slowly learning

pro inverter PROGYS 200 FV PFC CEL+tig lift

OA Oxyflam 1000 cutting and welding gas torch

There ya go! Sometimes a little tinkering with it does more than thousands of words.olek wrote: Well so the arc force regulation , when there is one, , is possibly the "fine setting" ? WIth zero arc force I noticed a very buttery arc, not so unpleasant but I did put arc force back trying 10 20 30 until I find a strenght that suits my need

Mixing that regulation and amps is more difficult, at that point I do not understand yet very well what makes what.

But its comingFor instance I think raising arc force and lowering amps may fight too strong spatter while allowing enough penetration.

In the cert. courses I took, there was a 15 min. instructional followed by 3.75 hrs. of practice.

PeteM wrote:There ya go! Sometimes a little tinkering with it does more than thousands of words.olek wrote: Well so the arc force regulation , when there is one, , is possibly the "fine setting" ? WIth zero arc force I noticed a very buttery arc, not so unpleasant but I did put arc force back trying 10 20 30 until I find a strenght that suits my need

Mixing that regulation and amps is more difficult, at that point I do not understand yet very well what makes what.

But its comingFor instance I think raising arc force and lowering amps may fight too strong spatter while allowing enough penetration.

In the cert. courses I took, there was a 15 min. instructional followed by 3.75 hrs. of practice.

"I think " means "I have noticed that, but I am not so sure"

Pianos , restorer and tuner

Dedicated to learn welding since april

slowly learning not complaining of doing beads and beads

not complaining of doing beads and beads

pro inverter PROGYS 200 FV PFC CEL+tig lift

OA Oxyflam 1000 cutting and welding gas torch

Dedicated to learn welding since april

slowly learning

pro inverter PROGYS 200 FV PFC CEL+tig lift

OA Oxyflam 1000 cutting and welding gas torch

Return to “Stick Welding/Arc Welding - Shielded Metal Arc Welding”

Jump to

- Introductions & How to Use the Forum

- ↳ Welcome!

- ↳ Member Introductions

- ↳ How to Use the Forum

- ↳ Moderator Applications

- Welding Discussion

- ↳ Metal Cutting

- ↳ Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- ↳ Mig and Flux Core - gas metal arc welding & flux cored arc welding

- ↳ Stick Welding/Arc Welding - Shielded Metal Arc Welding

- ↳ Welding Forum General Shop Talk

- ↳ Welding Certification - Stick/Arc Welding, Tig Welding, Mig Welding Certification tests - Welding Tests of all kinds

- ↳ Welding Projects - Welding project Ideas - Welding project plans

- ↳ Product Reviews

- ↳ Fuel Gas Heating

- Welding Tips & Tricks

- ↳ Video Discussion

- ↳ Wish List

- Announcements & Feedback

- ↳ Forum News

- ↳ Suggestions, Feedback and Support

- Welding Marketplace

- ↳ Welding Jobs - Industrial Welding Jobs - Pipe Welding Jobs - Tig Welding Jobs

- ↳ Classifieds - Buy, Sell, Trade Used Welding Equipment

- Welding Resources

- ↳ Tradeshows, Seminars and Events

- ↳ The Welding Library

- ↳ Education Opportunities