Page 1 of 1

Re: Prevent Aluminium monkey bars from twisting.

Posted: Sat Apr 08, 2017 4:55 pm

by exnailpounder

BramR wrote:Thanks for the replies guys!

I'll take mky time tacking and welding. As i read your posts i'm not that afraid that i'll get a helicoil.

I'll start in a week or two, and i will keep you informed. Till then i'll keep practicing. I started Tig welding three weeks ago. I got some box and round to practice the bulk of the welds.

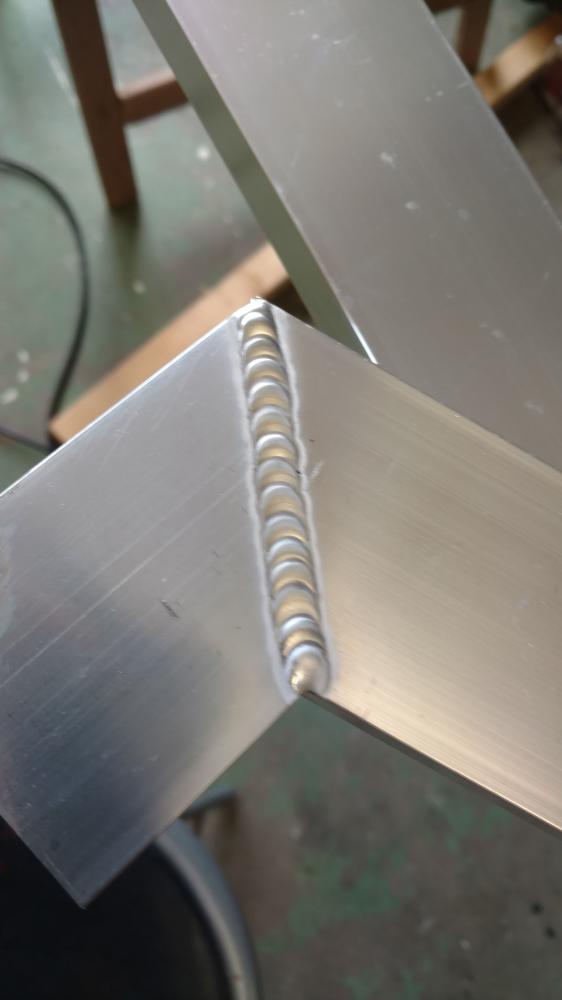

Here a sample of my lastest test weld. I'm not at all disapointed. Hope i can get most of the welds like this.

Test weld.JPG

I'll keep you informed of the progress.

That is beautiful! Three weeks??? WOW! If you drill your bars into the box tube so that you're not relying on welds then you'll be fine. Most in-the-know welders won't make treestands or ladders out of AL because of the liability. Even ladder manufacturers use mechanical fasteners on their rungs or they bore and crimp them to eliminate the weak link, which is a weld. Unless you have 400 lb. kids I wouldn't worry

You obviously have welding and mechanical knowledge so I say weld on...and let us see the final product.

Re: Prevent Aluminium monkey bars from twisting.

Posted: Wed Apr 26, 2017 1:14 pm

by BramR

The raw materials have arrived.

- 1493226719424630777678.jpg (68.52 KiB) Viewed 1528 times

Re: Prevent Aluminium monkey bars from twisting.

Posted: Wed Apr 26, 2017 5:07 pm

by LtBadd

BramR wrote:The raw materials have arrived.

Ok lets see this go together with photos of your process

Re: Prevent Aluminium monkey bars from twisting.

Posted: Wed Apr 26, 2017 5:39 pm

by ex framie

If you drill your bars into the box tube so that you're not relying on welds then you'll be fine.

^^^^^^^^^^^

That is excellent advice, eliminates the single point of failure of the weld.

Good luck and remember no photos, it didn't happen

Re: Prevent Aluminium monkey bars from twisting.

Posted: Thu Apr 27, 2017 2:53 pm

by BramR

- IMG_20170427_204958813.jpg (96.96 KiB) Viewed 1512 times

- IMG-20170427-WA0018.jpeg (33.27 KiB) Viewed 1512 times

Feel free to comment.

Re: Prevent Aluminium monkey bars from twisting.

Posted: Thu Apr 27, 2017 5:58 pm

by jernigan78

Pretty damn nice welds for doing ally for only 3 weeks! Nice job! Just make sure youre getting the weld bead down into the joint and penetrating. I only say this because I have made this mistake when I first started on ally and tried to weld pipe. It looked great on the surface, but when I cut it in half, there was a lack of penetration in the root of the joint. Kinda like it bridged over, and not down.

I would do as other have suggested though. Drill holes in the box tube and insert the crossbars. will be much stronger, and make life a bunch easier when youre jigging it up.

Re: Prevent Aluminium monkey bars from twisting.

Posted: Fri Apr 28, 2017 1:21 pm

by BramR

I sliced a box section in halve to check the weld. As you look close there is a line in the bead. Is this the residue of the oxide that floated on the penetration?

- 1493399734973403799610.jpg (35.46 KiB) Viewed 1492 times

This is the inside of the tube.

- 1493399805033758253074.jpg (28.17 KiB) Viewed 1492 times

This is the same weld from the outside. I think I started to cold, that is were there is lack of penetration.

(The black blob on the right tube is were I ran out of gas

)

Re: Prevent Aluminium monkey bars from twisting.

Posted: Fri Apr 28, 2017 4:03 pm

by Rick_H

BramR wrote:I sliced a box section in halve to check the weld. As you look close there is a line in the bead. Is this the residue of the oxide that floated on the penetration?

1493399734973403799610.jpg

This is the inside of the tube.

1493399805033758253074.jpg

This is the same weld from the outside. I think I started to cold, that is were there is lack of penetration.

(The black blob on the right tube is were I ran out of gas

)

Opps...we've all run out of gas.

Pictures make it hard, but are you sure that is not a crack running up the bead, that is what it looks like to me? Crank the heat up and burn it in...

Like others if I was building this Id drill holes, run fillets on the inside and button weld the outside if your go all the way through with the bars. Drilling as long as you can drill straight (LOL) will make alignment much easier.

Re: Prevent Aluminium monkey bars from twisting.

Posted: Fri Apr 28, 2017 4:35 pm

by exnailpounder

That sure does look like a crack on the bottom of that weld. Even though it looks like you got great penetration, that bulging metal is your base metal that is sagging down and never fused together. Make a small gap between your pieces so when you weld, you will melt in on both sides and that will make a little keyhole that you will dip into. What you did was the same as welding over the top of a crack. Your welds sure look nice though.

Re: Prevent Aluminium monkey bars from twisting.

Posted: Fri Apr 28, 2017 6:11 pm

by Olivero

exnailpounder wrote:That sure does look like a crack on the bottom of that weld. Even though it looks like you got great penetration, that bulging metal is your base metal that is sagging down and never fused together. Make a small gap between your pieces so when you weld, you will melt in on both sides and that will make a little keyhole that you will dip into. What you did was the same as welding over the top of a crack. Your welds sure look nice though.

Sure does and crack kills, so be careful with that. Before hanging anybody or anything on any item I build, I tend to put it to the ultimate retard test to make sure its all good.

Re: Prevent Aluminium monkey bars from twisting.

Posted: Fri Apr 28, 2017 7:11 pm

by MarkL

BramR wrote:As you look close there is a line in the bead. Is this the residue of the oxide that floated on the penetration?

That's blistering on the back of the weld, from too much heat. It should look like the start of the weld where it was colder and you just see the original joint between the two pieces of material. Excess heat is also what causes the longitudinal cracking along the weld. I'd try moving a bit faster and/or reducing the current.

Re: Prevent Aluminium monkey bars from twisting.

Posted: Sat Apr 29, 2017 3:04 pm

by BramR

Guys, it's finished.

The good news is the welds are fine. The bad news is I probably should have used a bigger box profile. For the girls it's fine, for me it's a bit to flexible.

- IMG_20170429_202528055.jpg (58.61 KiB) Viewed 1378 times

- IMG_20170429_203229282.jpg (62.47 KiB) Viewed 1378 times

Could be that I'll make another one.

What a learner!!! There are some peppery joints. Mostly I think from my filler rod that got to far from the puddle. Or me trying to fill com a wrong angle.

Had a lot of fun & learned a lot.

Re: Prevent Aluminium monkey bars from twisting.

Posted: Sat Apr 29, 2017 5:51 pm

by nelson

I would have buttressed that angle with some 1/4 plate. Don't have my trig table out but hang 100 lb on it and the forces at that weld are likely over 1000 lb.