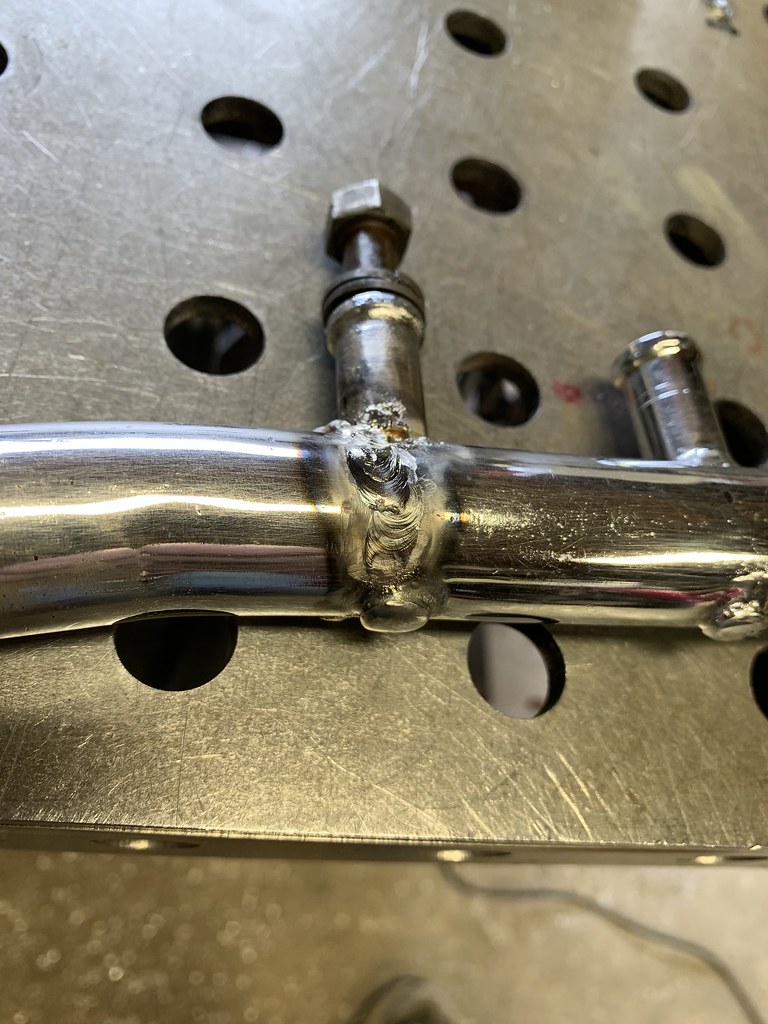

- round pipe, mild steel -- chrome plated. It's about 18" long, and is a mounting bracket for Harley exhaust pipes. I'll remove it tomorrow & get a better look at this crack

- ~ 1" diameter (maybe 3/4")

- ~ 1/8" wall thickness

- need to repair a crack around most of the diameter

- I intend to TIG the repair (obviously, but only if it makes sense)

- not really worried about corrosion. Although keeping the remaining chrome in tact would be nice (but not mandatory).

- bevel the crack out.... maybe drill the ends of the crack ? or just weld it with chrome in place ?

- grind the chrome off.... within (say) 1/2" of the crack ? or just weld it with chrome in place ?

- use a preferred filler rod ? e.g. Regular ER70S2 ? or Stainless ? or Silicon Bronze ? or ?

P.S. I don't have any practice pieces that are chromed, so I only get 1 shot at getting this right.