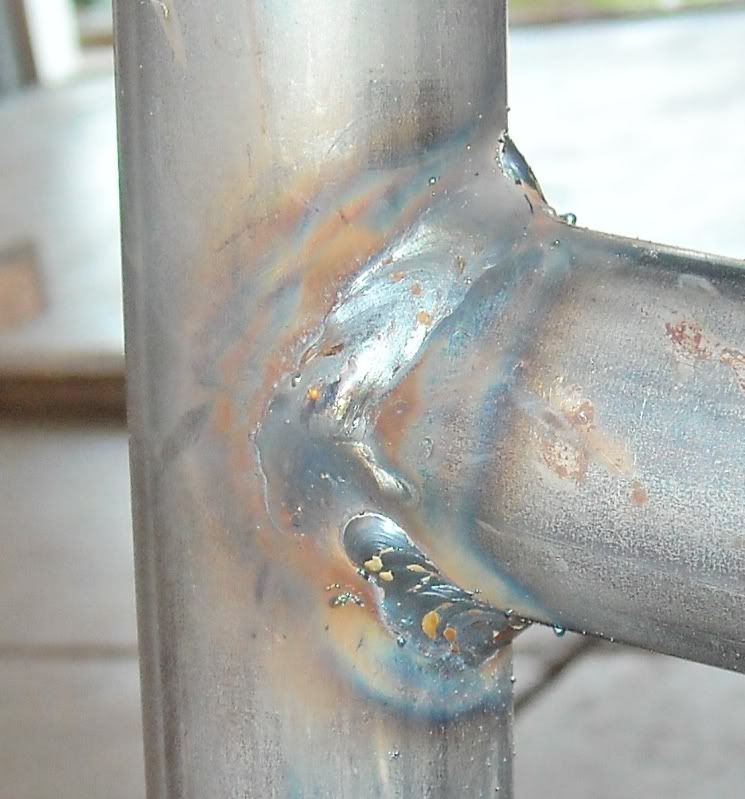

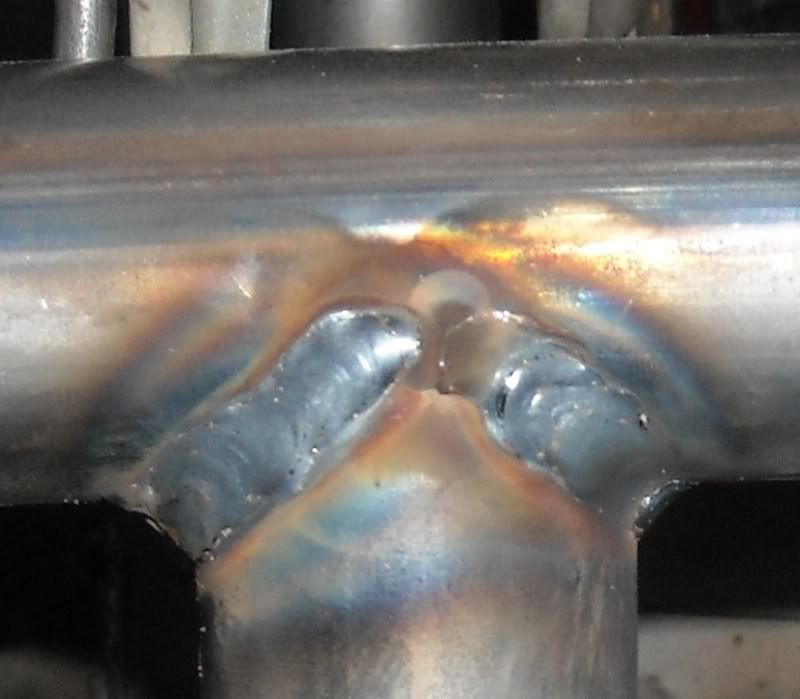

First post here. I have been welding for a while now and I have come to the conclusion that the quality of my welds have been in my opinion satisfactory but not to the level that I want them to be. I have been doing online research on the subject and trying different things so now I am looking to improve my consistence and quality of my welding.

I have a bunch of pictures of some of my practice and I have circled some of them that look decent but I am open to any criticism on all of the welds even the ones that are not that good just to get me on the right path. Feel free to ask me any questions as well.

Thanks for the support!

Cory

1

2

3

4

5

6

7

8

9

10

11