Page 1 of 2

Spray transfer

Posted: Fri Feb 24, 2017 11:55 pm

by Farmwelding

I'm curious about spray transfer and think I'm gonna try it out with a Millermatic 252 at my school. For practice purposes, and to just get familiar with the difference between short circuit and spray, does it matter so much if I use 75/25 gas? Also, any tips for spray transfer.

Re: Spray transfer

Posted: Sat Feb 25, 2017 12:01 am

by weldin mike 27

Turn the welder up as high as it can go, turn the wire down untill it hisses, then slowly turn the wire up until you get a beautiful frying/cracking/material tearing sound. That's spray. 75/25 may work but a tri mix with som O2 in it will bring the boyz to the yard. Proceed to weld thicker than 1/8 in the flat and horizontal pos. Keep the speed up so your arc burns on to fresh metal all the time.

Re: Spray transfer

Posted: Sat Feb 25, 2017 12:04 am

by Farmwelding

weldin mike 27 wrote:Turn the welder up as high as it can go, turn the wire down untill it hisses, then slowly turn the wire up until you get a beautiful frying/cracking/material tearing sound. That's spray. 75/25 may work but a tri mix with som O2 in it will bring the boyz to the yard. Proceed to weld thicker than 1/8 in the flat and horizontal pos. Keep the speed up so your arc burns on to fresh metal all the time.

What size metal would you recommend. 1/8", 1/4",3/8"-maybe? I'll have to go with 75/25 no matter what so I'll let you know and hopefully post some pics.

Re: Spray transfer

Posted: Sat Feb 25, 2017 12:06 am

by weldin mike 27

You can weld anything more than 1/8th inch because the weld pool will melt in almost that deep.

Re: Spray transfer

Posted: Sat Feb 25, 2017 12:08 am

by MinnesotaDave

Like he said, need your volts high - note the volts he says in the video.

You may not get into spray mode with the gas you have - note the gas choices in the side bar of the video for mild steel.

https://m.youtube.com/watch?v=IHkbh0oKv_g

Re: Spray transfer

Posted: Sat Feb 25, 2017 12:12 am

by Farmwelding

MinnesotaDave wrote:Like he said, need your volts high - note the volts he says in the video.

You may not get into spray mode with the gas you have - note the gas choices in the side bar of the video for mild steel.

https://m.youtube.com/watch?v=IHkbh0oKv_g

My question is then how does the gas affect the arc. If the voltage is up to like 29-30 volts, why does the gas prevent it?

Re: Spray transfer

Posted: Sat Feb 25, 2017 2:22 am

by Rupes

I use it when I can, its a great process. No penetrations or issues, just really fast and hot. I use a proprietary mix here from BOC called Argoshield Light for general purpose mig stuff. Its made up of the following.

3.1% Oxygen, 5% Carbon Dioxide 91.9% Argon

I don't think its ideal for spray but certainly works. Short circuit is exactly that, the wire creates a short on the material being welded and melts, imparting some heat into the base metal etc. Gas shields arc and molten metal from atmosphere.

With spray, I think the higher voltage forms a hotter plasma between wire and base metal melts the wire into fine droplets before it touches the base metal. Gas composition/type has a direct effect on the plasma characteristics there for it works better with some mixes than others. And I think it also depends how much grunt the machine has, pretty sure that bit of O2 helps it go into spray with a bit easier.

Re: Spray transfer

Posted: Sat Feb 25, 2017 9:47 am

by MinnesotaDave

Why doesn't your teacher know and teach this?

This Lincoln book covers your questions, and some other side questions that may result, from pages 1-17.

https://www.lincolnelectric.com/assets/ ... /c4200.pdf

If you need clarification, that reading should give you the background needed to be specific in your questions

Re: Spray transfer

Posted: Sat Feb 25, 2017 10:08 am

by Farmwelding

MinnesotaDave wrote:Why doesn't your teacher know and teach this?

This Lincoln book covers your questions, and some other side questions that may result, from pages 1-17.

https://www.lincolnelectric.com/assets/ ... /c4200.pdf

If you need clarification, that reading should give you the background needed to be specific in your questions

The curriculum for our metals classes combine machining and welding. With this the classes are 45 minutes a day for one semester. We have a limited number of machines on all fronts and limited space to work efficiently for 16+ students. There is simply not enough time in the actual classes. I am on an independent study during one of those classes and I help students and am just practicing. I'll probably do this when they move to machining or before they are done with their intro project.

Re: Spray transfer

Posted: Sun Feb 26, 2017 12:40 am

by Otto Nobedder

If you have access to a helium tri-mix or a 90/10 argon/co2, spray is easily in your grasp. For an .035 wire, figure 27V and 225-250 IPM as a starting point, and listen for that quiet hiss previously described.

I have achieved spray with 75/25, but at closer to 32 volts on a HUGE three-phase Lincoln power source.

Steve S

Re: Spray transfer

Posted: Sun Feb 26, 2017 12:58 am

by Farmwelding

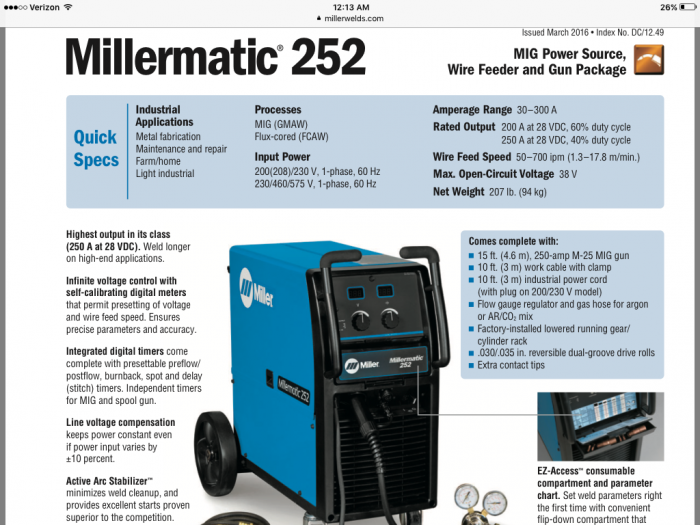

So with 75/25 gas, crank the 252 up as high as it will go and adjust wore feed speed accordingly. What is the maximum settings on the 252 for voltage-maybe I'm not reading it right, but it says 38VDC on the 252 page from Miller.

https://www.millerwelds.com/equipment/w ... der-m00218

So realistically it may work with this machine and we'll play it as time goes. Thanks for the answers.

Re: Spray transfer

Posted: Sun Feb 26, 2017 2:17 am

by MinnesotaDave

Farmwelding wrote:So with 75/25 gas, crank the 252 up as high as it will go and adjust wore feed speed accordingly. What is the maximum settings on the 252 for voltage-maybe I'm not reading it right, but it says 38VDC on the 252 page from Miller.

https://www.millerwelds.com/equipment/w ... der-m00218

So realistically it may work with this machine and we'll play it as time goes. Thanks for the answers.

The Miller is rated at 250 amps at 28 volts.

Weld voltage is not the same as open circuit voltage.

If I was your teacher I'd tell you to go try maxing out your own machine.

- image.png (369.33 KiB) Viewed 1800 times

Re: Spray transfer

Posted: Sun Feb 26, 2017 5:55 am

by weldin mike 27

I should point out that I only use machines over 300-400 amps, even at Tradeschool. But theroretically, yes. If you have access to .045 wire, that'll help as well.

Re: Spray transfer

Posted: Mon Feb 27, 2017 8:20 pm

by Farmwelding

Would using 100% argon be a better way to achieve spray transfer. I have that as my other option as well.

Re: Spray transfer

Posted: Mon Feb 27, 2017 8:40 pm

by MinnesotaDave

Farmwelding wrote:Would using 100% argon be a better way to achieve spray transfer. I have that as my other option as well.

Page 14 and 15 of the document I linked to you will answer this for you

Re: Spray transfer

Posted: Mon Feb 27, 2017 9:32 pm

by Poland308

Thanks for that link Dave I spent an hour reading a lot of stuff I didn't know about Mig that I wish I had read a long time ago.

Re: Spray transfer

Posted: Mon Feb 27, 2017 10:32 pm

by MinnesotaDave

Poland308 wrote:Thanks for that link Dave I spent an hour reading a lot of stuff I didn't know about Mig that I wish I had read a long time ago.

You're very welcome - Lincoln puts out some quality literature in my opinion

...now if I could just remember all of it I wouldn't have to re-read it every so often

Re: Spray transfer

Posted: Mon Feb 27, 2017 10:38 pm

by Farmwelding

MinnesotaDave wrote:Poland308 wrote:Thanks for that link Dave I spent an hour reading a lot of stuff I didn't know about Mig that I wish I had read a long time ago.

You're very welcome - Lincoln puts out some quality literature in my opinion

...now if I could just remember all of it I wouldn't have to re-read it every so often

Yeah I see Lincoln does a lot of educational stuff. Videos, literature, training systems the whole works. They have the upper hand for sure on that page.

Re: Spray transfer

Posted: Tue Feb 28, 2017 10:45 pm

by Farmwelding

Well I talked with moser fab and he runs spray with 75/25 with his 252 often. I gotta wait antiher week because of ACT testing and my teacher going to a conference. And of course we have had its just that our welding supply store dropped the gas off at the bus barn and not our room so they have to come pick up the empties still and then somebody has to move 200 yards on a cart.

Re: Spray transfer

Posted: Wed Mar 01, 2017 8:10 am

by Poland308

200 yards. That's a small job site. Wait till you get on a average one where they leave the bottles at the front gate and you cart them a 1/4 mile through mud, and the rock they put down on a construction site that's somewhere in size between your head and your fist. Oh and the cart always has one flat tire when you need it.

Re: Spray transfer

Posted: Wed Mar 01, 2017 9:00 am

by Farmwelding

Hah. This is at my school so it's blacktop but usually they ring them at least to the door to pick them up. My teacher told me where they were, we were doing the ACT at the time so nothing I could have done anyways, and when he told me I immediately said that there is no way in hell in bringing down by hand. Cause I'm sure I couldn't use a cart because it isn't safe for me. I am sure our schools safety coordinator, who we got along fine without for 50 years, would find it unsafe

Funny part is by me taking a safety test and my local tech school I am pretty much more qualified for his job than he is. I guess good safety coordinators and inspectors are like good weld inspectors

Re: Spray transfer

Posted: Wed Mar 01, 2017 3:22 pm

by MinnesotaDave

Nothing wrong with a 2 wheel cart. They roll fine - put a strap on it.

Re: Spray transfer

Posted: Thu Mar 02, 2017 6:01 am

by weldin mike 27

We have these "safe" trollies that have a winch on them to lift the gas bottle up to the back of the welder. problem is they were designed by a ham fisted mong. They have almost no leverage and almost no ground clearance. Didn't stop them costing about a K i reckon.

Re: Spray transfer

Posted: Thu Mar 02, 2017 9:24 am

by exnailpounder

MinnesotaDave wrote:Nothing wrong with a 2 wheel cart. They roll fine - put a strap on it.

Be advised...he didn't tell you to use a strap-on..he said to use a strap

Re: Spray transfer

Posted: Thu Mar 02, 2017 2:04 pm

by MinnesotaDave

exnailpounder wrote:MinnesotaDave wrote:Nothing wrong with a 2 wheel cart. They roll fine - put a strap on it.

Be advised...he didn't tell you to use a strap-on..he said to use a strap

Who knew the hyphen had so much power