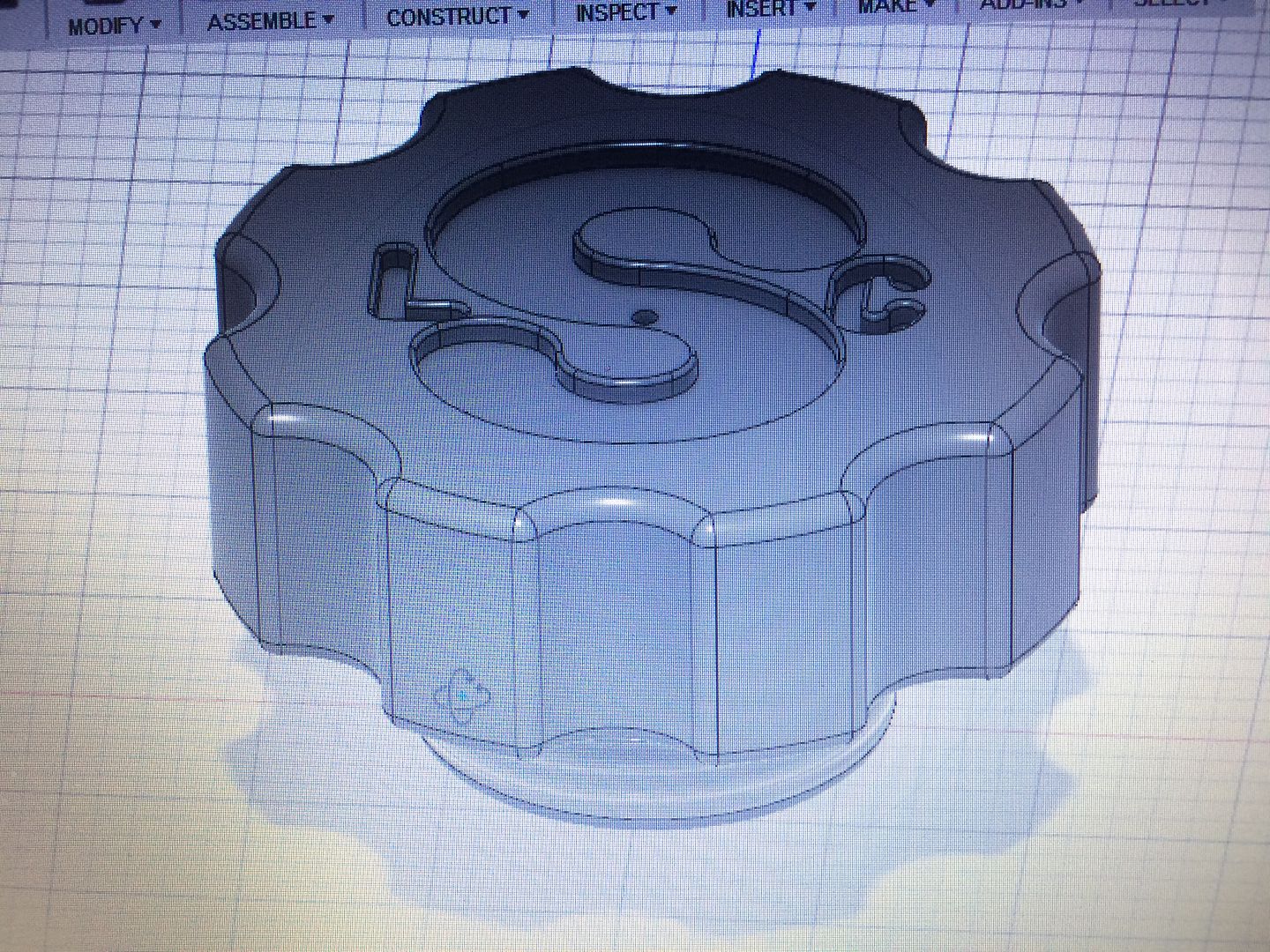

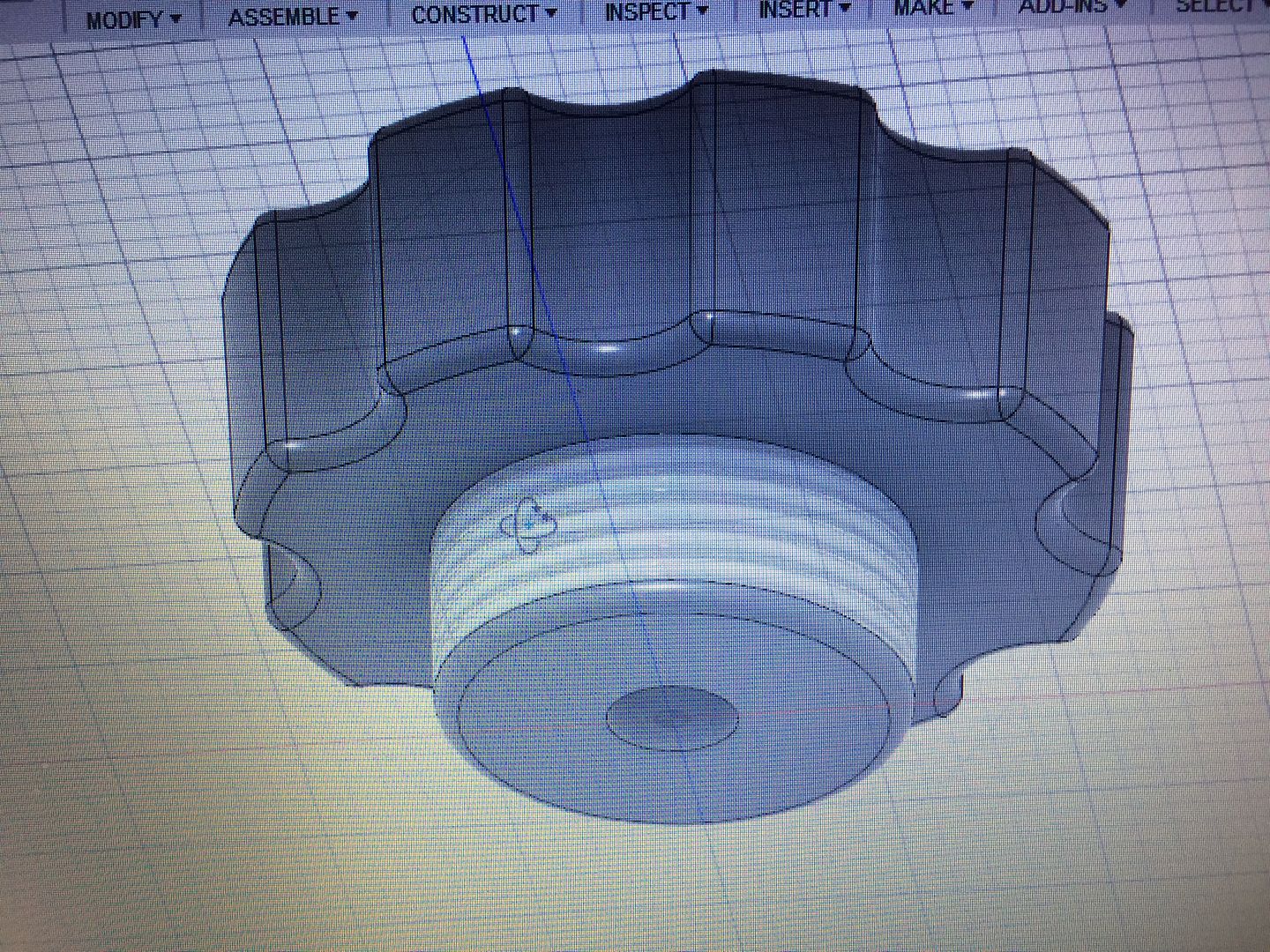

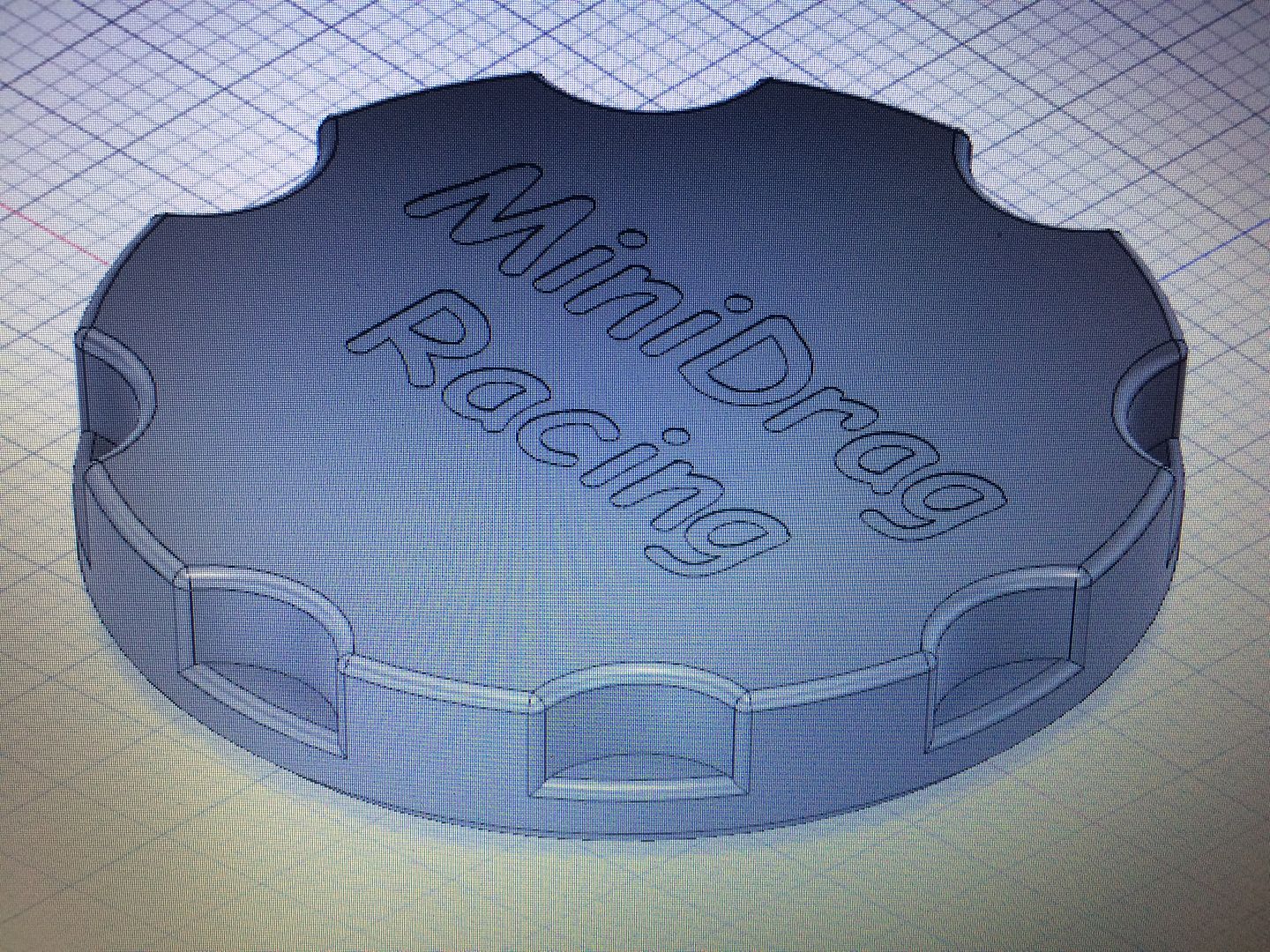

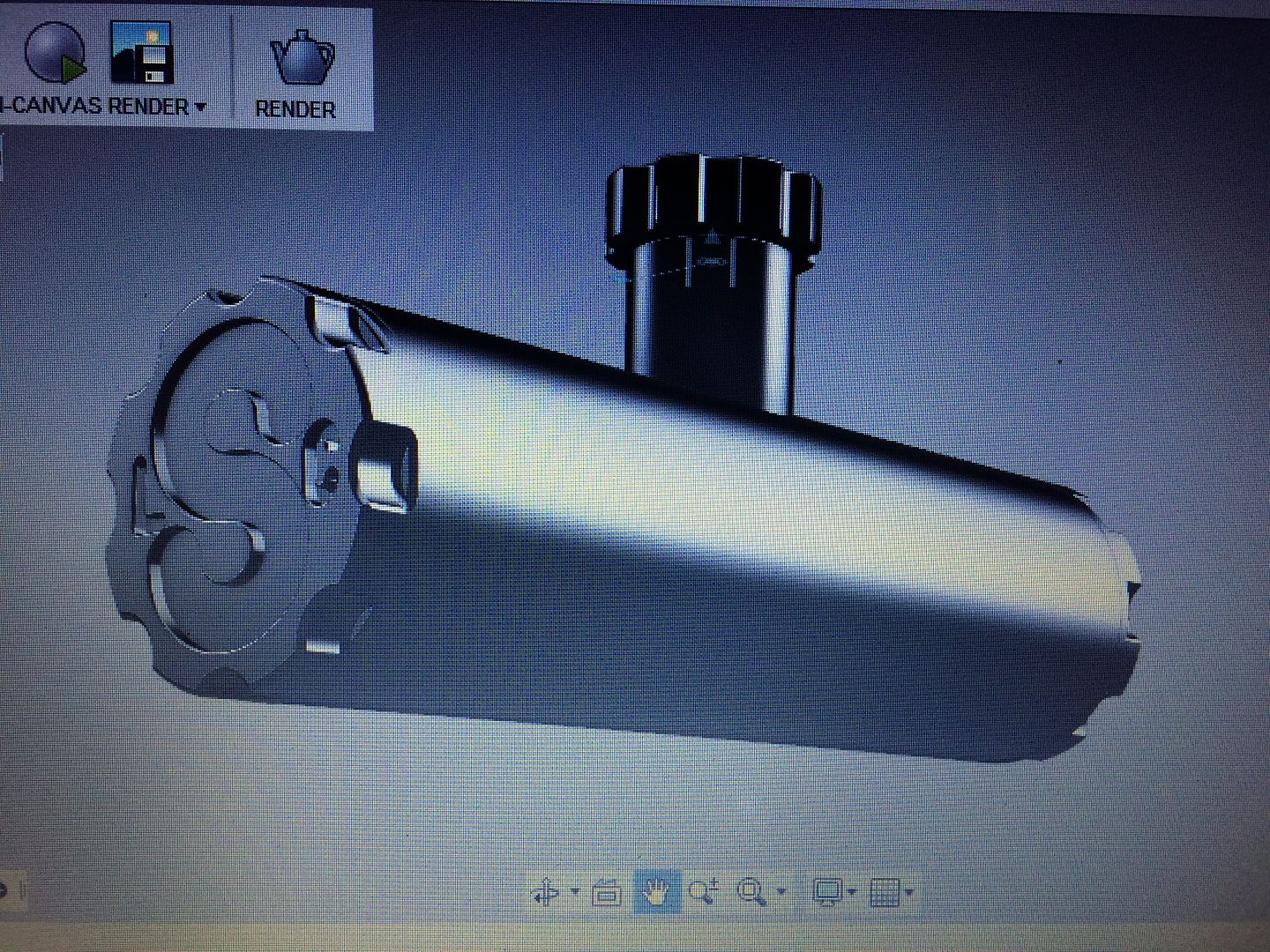

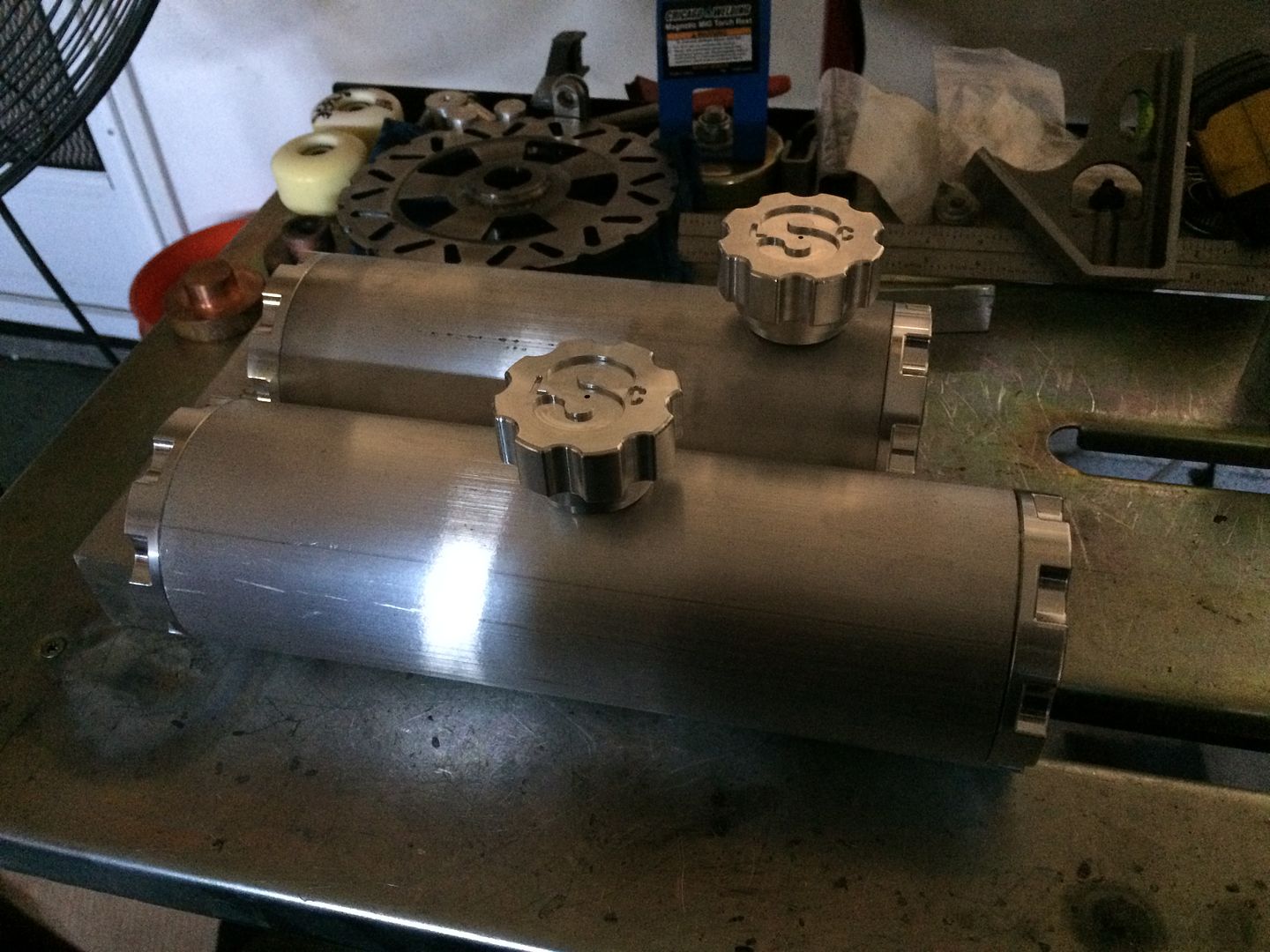

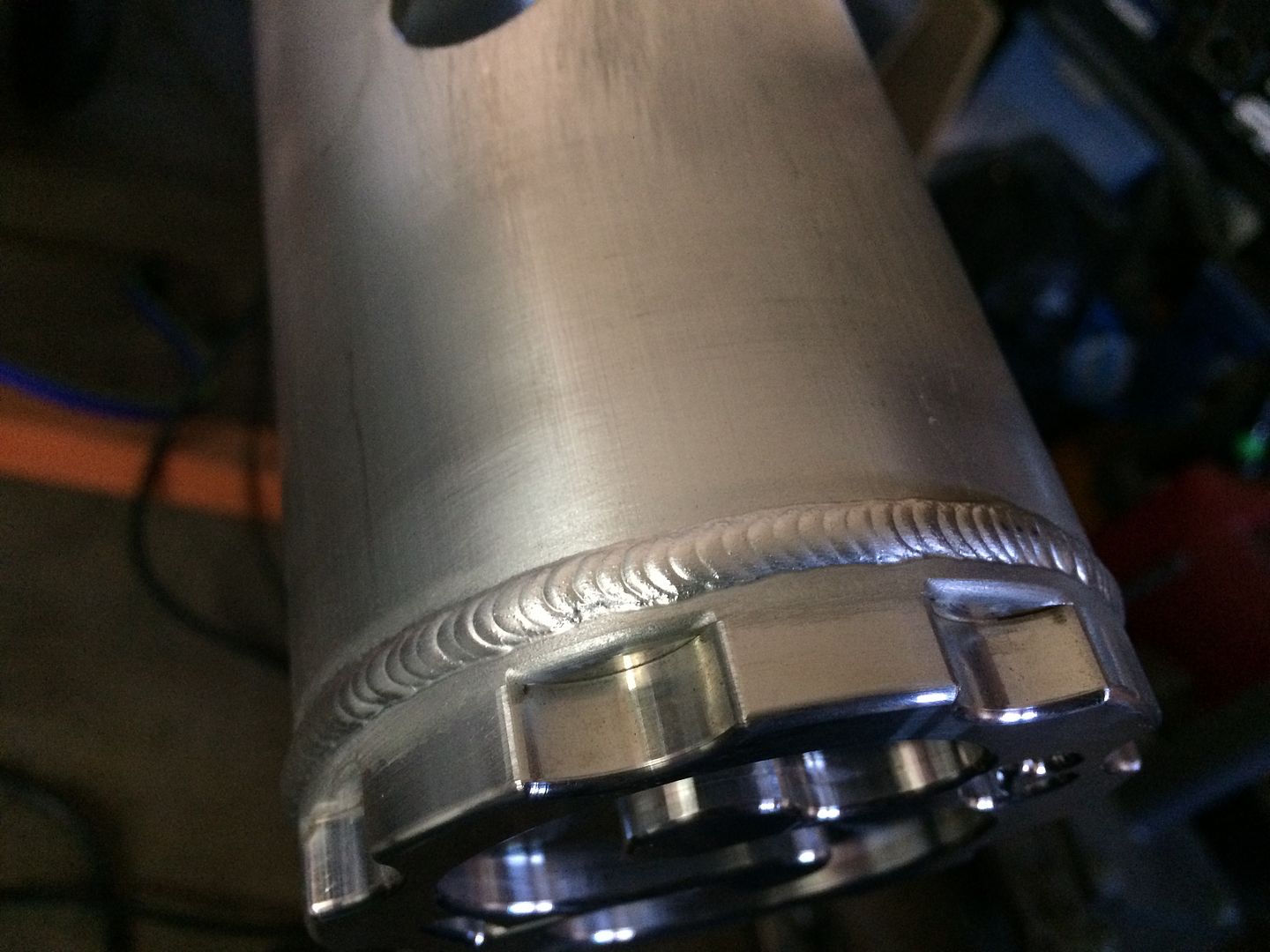

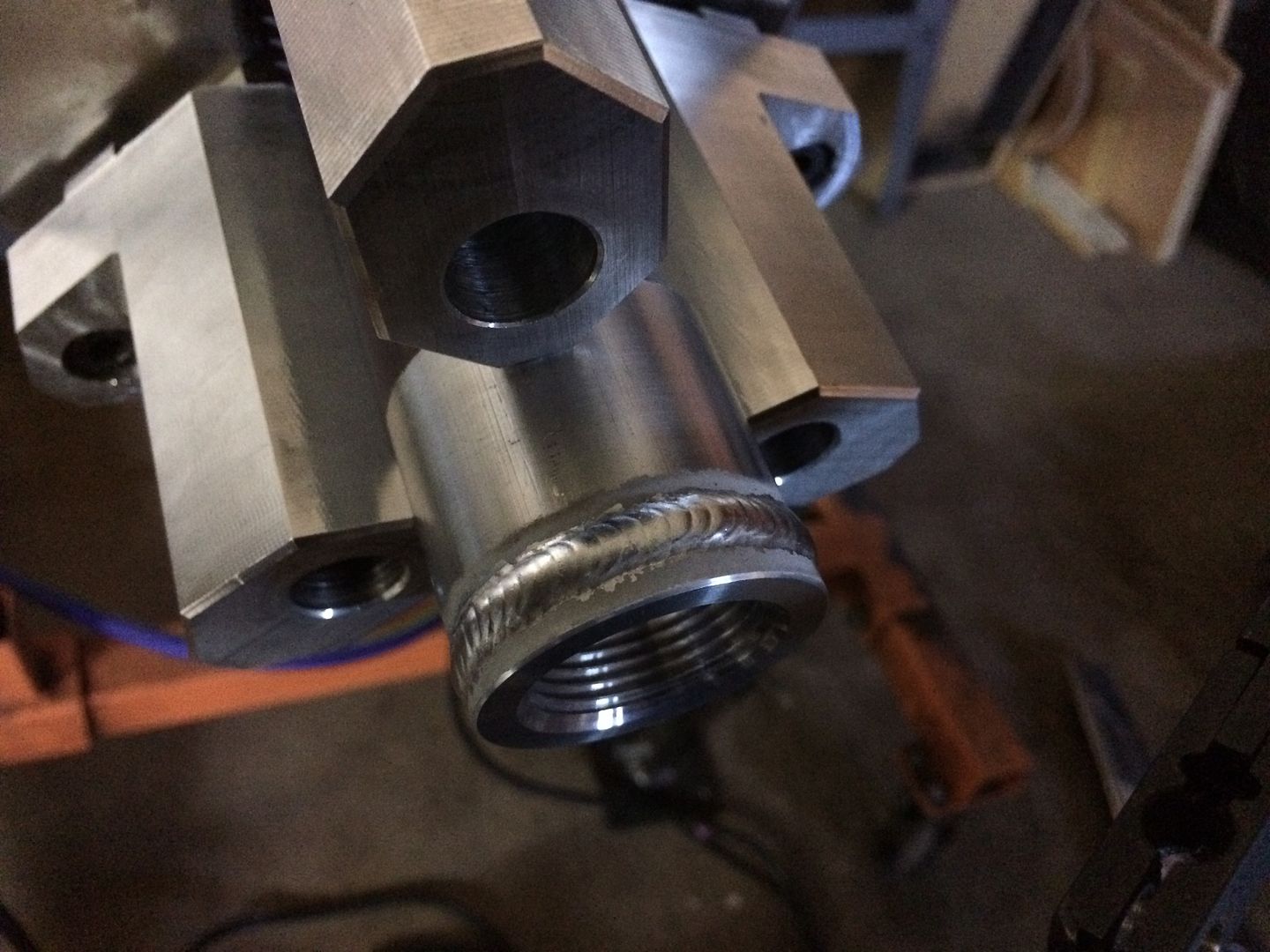

for this set of "tanks" I designed the end caps to match the filler cap... but i had the intention of smoothing out the welds around the end caps to make it appear one piece...

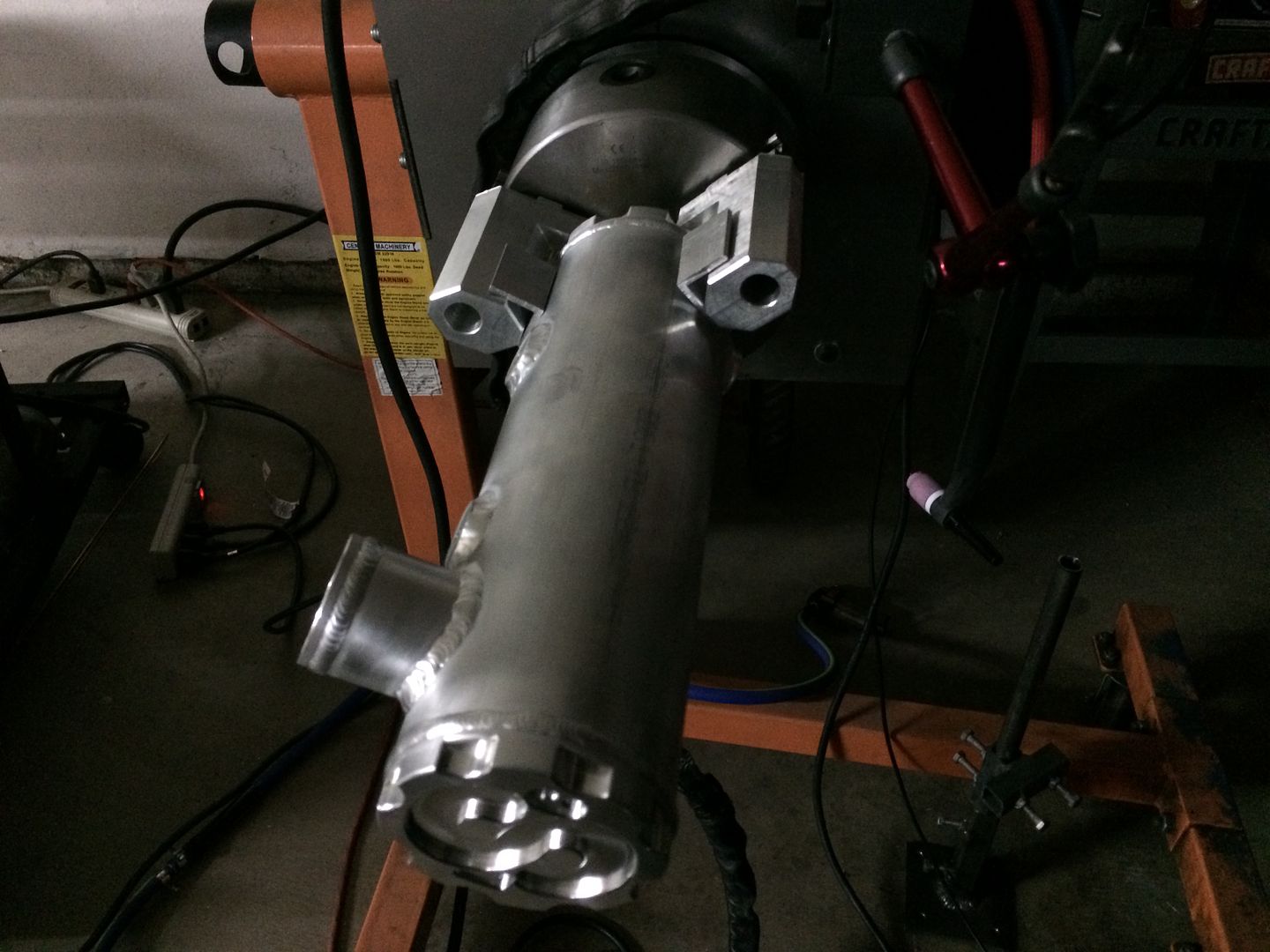

there seems to be info all over the place on this.. i welded this particular tank with 5356... i do have some 4943 coming and will more than likely be using that on anything that will not get a coating, as it is supposedly better/stronger/etc... not sure if it is necessary...

question is, what is the actual "rule" if any, as it relates to grinding/sanding down the welds on something like this... that may hold fuel or oil, etc... is there a way, other than to continue to gain experience and confidence with tig welding, where i can test, or tell if something should crack? is this something that happens right away, or can happen over time and without warning? with proper fusion, i should be able to smooth the weld polish or brush the material for a nice consistent finish and be fairly confident it will not crack? I do and will check for leaks under pressure (i checked this tank for leaks, there are none)... just trying to figure out how to gain confidence in what im trying to do as i go along, without having to wait for something to crack etc, if that makes sense... theoretically and hopefully nothing would... but i would like a way to tell for sure, if possible...

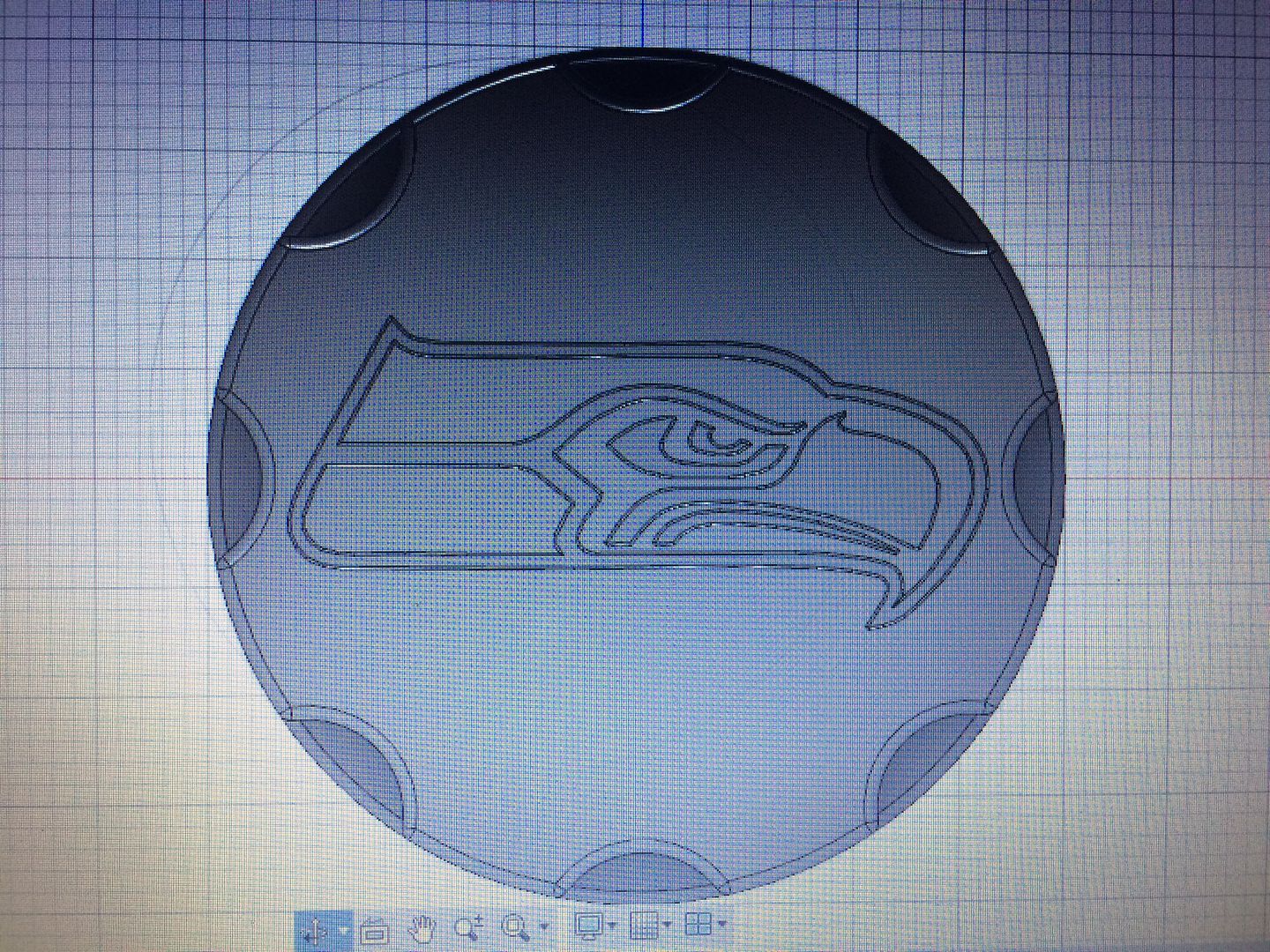

or is the hard fast rule that i should not ever... i have also designed two piece end caps, where the tank would be welded up and welds not touched and end caps bolted on too... but for these next several parts, i wanted to weld the end caps on... i would weld ends on the tank counter sunk, where the end cap would butt up against straight edges on the tank and be a nice uniform seam... i think i will go with this, for future if these go to new homes... but would like to have a decent answer before i smooth any welds off these next few parts...

will push a flat end cap in for the future ones and then weld a blind bung to bolt the end cap too, so i dont have to worry about this when building these in the future

and then bolt on the end cap