Page 1 of 1

Buildpro table?

Posted: Thu Mar 10, 2016 9:34 am

by griff

I run a small fab shop and I'm thinking about buying a buildpro table to help us out with projects. It's just me and a part time employee so I'd like to have something that helps me hold things in place since a lot of the time I can't get anyone to hold stuff for me. We do a good bit of small repetitive runs at times. Lots of 2-20 part quantities. Thoughts? For those that have used these, is it necessary to get a nitride coated table? I do a lot of MIG and TIG welding but basically no stick welding.

Re: Buildpro table?

Posted: Fri Mar 11, 2016 2:08 am

by dynasty200sd

Black Nitride helps with corrosion resistance. I have a few parts that have this treatment done on my AR-15. (if you are not familiar with black nitride it is actually infused into the surface layers of the metal instead of like coatings that lay on top of the surface.)

If you are interested in wanting to get one of these tables, and are not able to source one local to your area; checkout the website Trick-Tools. This is where I purchased my table because they offer free shipping for these tables.

If you keep the table oiled when not used, the steel plates will not really rust if any at all. I have the 2 ft x 3 ft Build Pro Table (a few topics down I started a topic about my table). I use "Fluid Film" (a lanolin based corrosion preventative and lubricant) to keep my plates almost rust free. I live 5 miles from the Gulf of Mexico, and you can see by my pictures how well the raw finish has held up, and this is the condition after 2 years of owning it where I live.

Re: Buildpro table?

Posted: Fri Mar 11, 2016 9:48 am

by griff

Thanks. Sounds like it's mostly for corrosion protection. I don't have any problem with my mill or lathe getting rusty so I think I'd be ok. I think I'll save my pennies. How are the tables as far as weld splatter sticking to them?

I've ordered from Trick Tools severals times before. I bought four of the stronghand corner clamps from them about 3 months ago and was really pleased with them. Unfortunately they are around a grand higher for the same stronghand part numbers as I have found other places. I wonder if they'll price match. My local welding shop quoted me higher than trick tools price plus freight which they couldn't tell me how much it would be until I ordered it.

Re: Buildpro table?

Posted: Fri Mar 11, 2016 6:36 pm

by dynasty200sd

I have yet to MIG on my table, just been TIG welding. I'd ask Jody (Site Admin / Owner of Welding Tips and Tricks) about MIG and the BuildPro Table. He uses a BuildPro at his welding shop in the Atlanta area. But, I do not see an issue if an anti-spatter spray is used or PAM Cooking Spray.

Re: Buildpro table?

Posted: Mon Mar 21, 2016 8:20 am

by griff

Yeah some anti spatter spray would probably be good. I'll send Jody a message and see what he says about it. I ordered my table last week. I can't wait until it gets here.

Re: Buildpro table?

Posted: Tue Mar 22, 2016 3:36 am

by dynasty200sd

griff wrote:I ordered my table last week. I can't wait until it gets here.

Locally, or from an online website? Which table size did you go with?

Re: Buildpro table?

Posted: Tue Mar 22, 2016 10:31 pm

by griff

I bought it from Industrial-toolcrib which is part of or somehow connected to Lehigh Valley Abrasives. I got the 94x46 table and the 120 piece tooling kit. I've got enough room for the table and I didn't want to have to buy another one later. A lot of our customer projects are around 4 to 5 feet. I've got one lined up that I have to lengthen 16 12' piece by 14". All of them are round tubing so I needed something good to clamp them to. I also have some products that I've been working on that this table will help build.

Re: Buildpro table?

Posted: Wed Mar 23, 2016 12:50 am

by dynasty200sd

griff wrote:I bought it from Industrial-toolcrib which is part of or somehow connected to Lehigh Valley Abrasives. I got the 94x46 table and the 120 piece tooling kit. I've got enough room for the table and I didn't want to have to buy another one later. A lot of our customer projects are around 4 to 5 feet. I've got one lined up that I have to lengthen 16 12' piece by 14". All of them are round tubing so I needed something good to clamp them to. I also have some products that I've been working on that this table will help build.

Have you seen the table leg adapter you can buy, so you can unbolt a plate to widen the table at that plate, and then attach the leg to the plate?

Re: Buildpro table?

Posted: Wed Mar 23, 2016 7:43 am

by griff

I sure have. I thought that was a really cool setup. I planned to make my own at some point.

Re: Buildpro table?

Posted: Tue Mar 29, 2016 9:19 am

by griff

I feel like a kid at christmas. I have been working off a 2x4 welding table with a top that isn't flat.

Re: Buildpro table?

Posted: Tue Mar 29, 2016 12:47 pm

by Otto Nobedder

"Like"!

Very nice. Congratulations.

Now, I'm jealous...

Steve S

Re: Buildpro table?

Posted: Tue Mar 29, 2016 1:45 pm

by griff

I already put it to use this morning. This is the pieces for a skid steer quick attach plate. They are outside corner joints around the edge that I don't want any overlap of material on so they are very hard to line up normally. I have to get someone to hold them. I was able to use 4 stops on the piece that's leaned over to get it to line up perfectly.

Re: Buildpro table?

Posted: Thu Mar 31, 2016 1:13 am

by Polobbie

I have the 78x38 table with two extension plates but without the nitride coating. I also have roughly 200 accessory items with it. I absolutely love it. I usually have many options for clamping up odd things and squaring weld ups is automatic. I have seen no oxidation whatsoever. However, I do keep my shop humidity controlled below 40% at all times. I tend to only TIG weld on it and use another heavy table for mig welding.

Re: Buildpro table?

Posted: Fri Apr 01, 2016 10:28 am

by griff

I really really like my table so far. I'm regretting putting off buying it for as long as I did. I bought the 120 piece tooling kit. I can see the need for having more tooling depending on the project. This will at least get me a good start and I can ad to it as I see fit. I wiped down the plates with anti spatter. Nothing seems to be sticking to it at all mig welding on it. I'm making sure the joints don't go directly to the table but have some air space. I will probably use this about equal for MIG vs TIG. I have to do mutliples of some fairly precises chassis pieces shortly. I can tell it's going to be way less headache.

Re: Buildpro table?

Posted: Sun Apr 30, 2017 1:26 am

by houdni

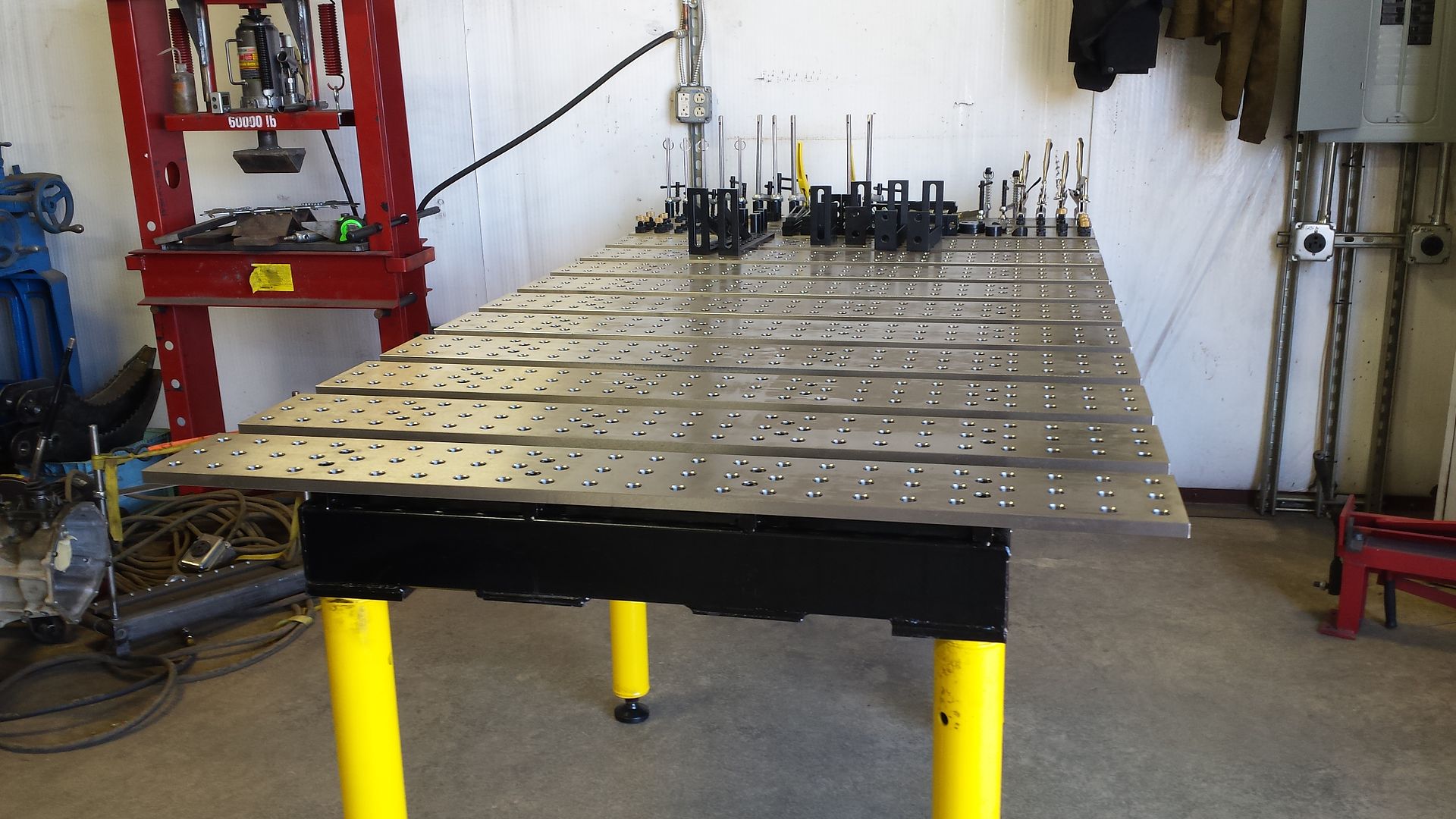

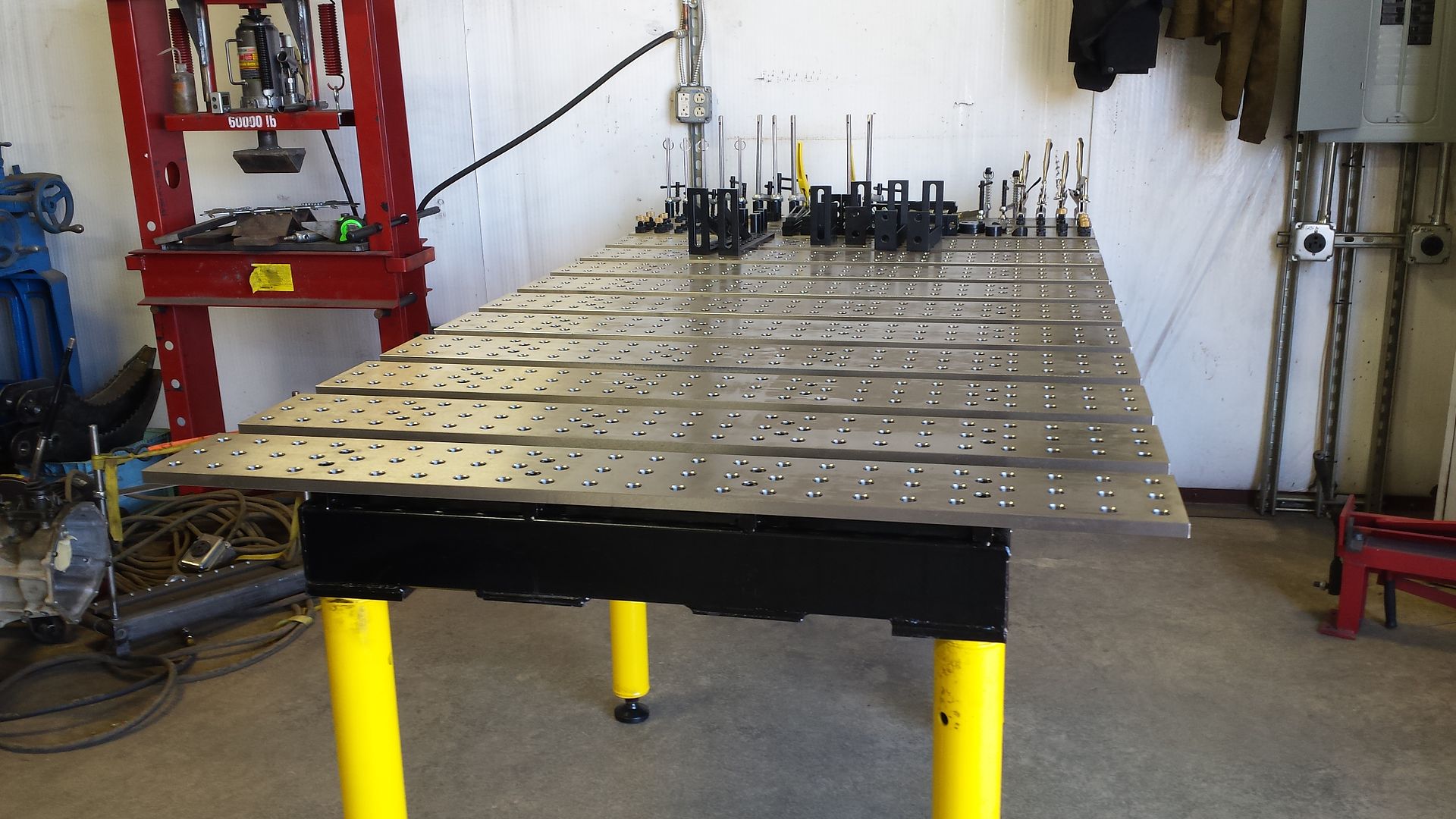

i started off with a certiflat table....it was a great introduction to these types of tables without the high cost investment...after almost 2 years of working with this table...ive decided to upgrade my table... the new table is the buildpro max thus no big gaps between plates.. 8' x 4'

Re: Buildpro table?

Posted: Wed May 03, 2017 12:59 pm

by pgk

Beautiful Table